|

|

進(jìn)口粘度計(jì) 流變儀 質(zhì)構(gòu)儀-廣州易測(cè)儀器有限公司 >>

WACO美國沃克 >> 鍍錫量?jī)x>> |

| |

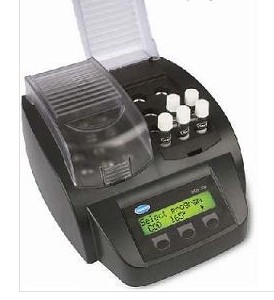

| STANNOMetal 9000 |

商品編號(hào):

商品編號(hào): |

201274511 |

商品規(guī)格:

商品規(guī)格: |

|

商品品牌:

商品品牌: |

美國WACO沃克 |

商品比較:

商品比較: |

|

商品庫存:

商品庫存: |

10臺(tái)

熱賣中

|

商品折扣:

商品折扣: |

0折

( 贈(zèng)送積分0分 ) |

瀏覽次數(shù):

瀏覽次數(shù): |

次 |

|

|

|

|

|

|

Accurately and quickly analyze tin and chrome coating thickness! |

Introduction

Stannomatics have been in use by tin mills, can makers, food canners and research laboratories throughout the world for over twenty years. Stannomatics have proven themselves to be so reliable that they have become a world standard for their purpose.

As good as Stannomatics are, the new STANNOMetal systems are even better. STANNOMetal is the first Windows based tin and chrome measurement system to use the accurate stannomaticmethod of measuring thickness.

STANNOMetaI 9000 is the only product to provide accurate tin coating analysis using the Windows operating systems. The system capitalizes on existing SUMETAL electrolitic cells by utilizing them with new hardware and software to provide a more accurate thickness detection system.

|

Operating Principles

STANNOMetal 9000 uses the ASTM STD A630.87 Method B (The Referee method). The method of measurement is a combination of the coulometric principle with a very accurate human-engineered design for easy, fast and reliable quality control work.

The current performs the electrolytic dissolution of a precisely delimited area of the sample. The amount of removed metal is measured on the basis of the relation between weight and the quantity of current invested in the process.

Sensitive and selective circuits monitor the deplating process. The system provides the operator with information regarding the deplating process. The operator is also presented with a live graph of the deplating process.

When the deplating process is completed, the software post-analyzes the graphs in order to accurately locate the end of each layer. At this point, the operator can override the detection process manually, save the graphs for future reference, proceed to perform additional measurements, or finish the report.

The system has been designed for complete ease of use and has been designed to require minimal training before actual measurements can take place. |

Features:

· Select units of measurement (gr/m sq. or LB/BB)

· Select standards from built-in tables (e.g., ASTM, EURONORM, ISO, 1351).

· Create a custom User Standard table

· Establish stripping conditions and control the rate of stripping.

· Change process parameters like current, according to the size of the tested area.

· Control, store, delete, sort or recall every report that has been generated.

· Automatic detection of layer transition points (manual override possible)

· Review graphs of previously measured samples

· Monitor electrolytic solution usage.

· Produce one-spot or three-spot reports on both 1-spot cells and 3-spot cells.

· Perform self-test and calibration verification procedures

· Perform backup procedures, or review information from backups.

· Perform standard maintenance functions (e.g., cleaning)

· Perform quick measurements (i.e., no standard needs to be selected) |

| Operating Procedure

The operator inserts the metal sample (strip, or actual sample) into the cell. Electrolytic fluid fills the cell and the cell is closed. Next, the measurement process can proceed, with top only, top & bottom or 3x top and bottom measurements. Profiles are presented for each of the measurements.

The data can be zoomed in or modified as needed. The next measurement can take place, or a new measurement, using a new standard.

The operator can also review and zoom on old profiles, saved previously. 3-spot systems can measure top only, the top and bottom of one spot, or all three spots. All of the measurements are taken concurrently.

For 1-spot systems, the operator can perform exactly the same type of measurements (top only, top & bottom for one spot, or three spots). When measuring three spots using a 1-spot system, the system measures them one after another instead of concurrently.

Reports look identical regardless of which type of system is in use - a 3-spot system, or a 1-spot system.

|

Specifications

| Metal Coating: |

Tin, Tin-Iron Alloy, Metallic chromium |

Standard Tables: |

Built-in ASTM, EuroNorm, ISO and user defined standard |

| Min Range: |

0.2 to 30 gr/m² (0.02 to 2.5 LB/BB) |

Electrolytic cell:

Options: |

Standard STC-4DM

Automatic cell (STC-4DA) automatic closing and filling

3 spots or 3 spots on rails |

| Max Range: |

TFS 5 to 1000 mg/m² (50 to 10000 mg/ft2) |

O/S: |

WindowsTM operating system |

| Chromium: |

tinplate more than 4 mg/m² |

Operation:

Option: |

Using mouse or remote control unit

Touch screen display |

| Test Channels: |

Single side, one spot, 3 spots |

Graphs: |

Graphs of deplating process, live during measurement and saved graphs |

| Method: |

coulometric with two electrodes

ASTM referee method (A636-87) |

Reports: |

Regular reports, 3 spots report (can be used with 1-spot or 3-spot cell) |

| Detection: |

Auto detection of end point, manual correction |

Database: |

storage of standards, reports and graphs |

| Deplating Rate: |

Multiple choice according to nominal coating |

Service: |

Easy maintenance and electrode replacement

Easy self test for localizing problems. |

Deplating Area:

Options: |

645mm² (1 sq. inch)

2580 mm² (4 sq. inch)

Small diameter (8mm min)

Strip from beaded can (8mm min) |

| |

|

| >>查看更多關(guān)于 美國WACO沃克 品牌的商品 |

|

|

|

|

| |

|

![]() |

MSN客服

MSN客服